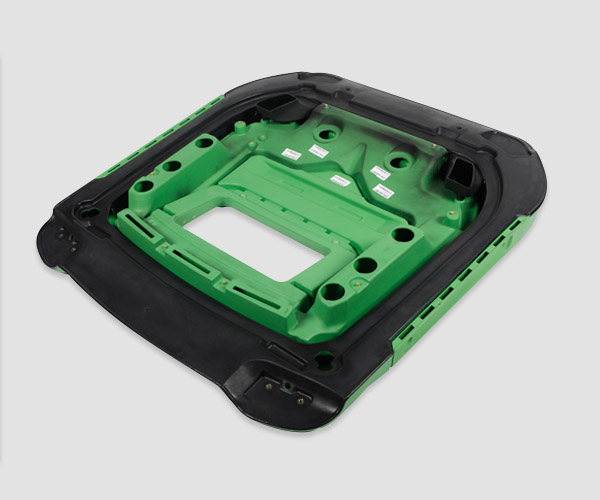

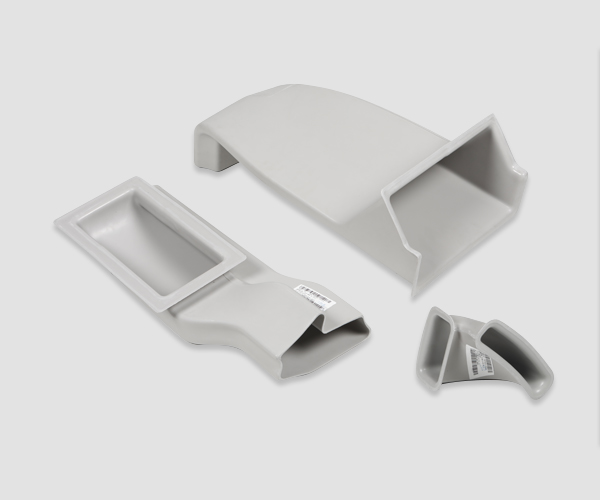

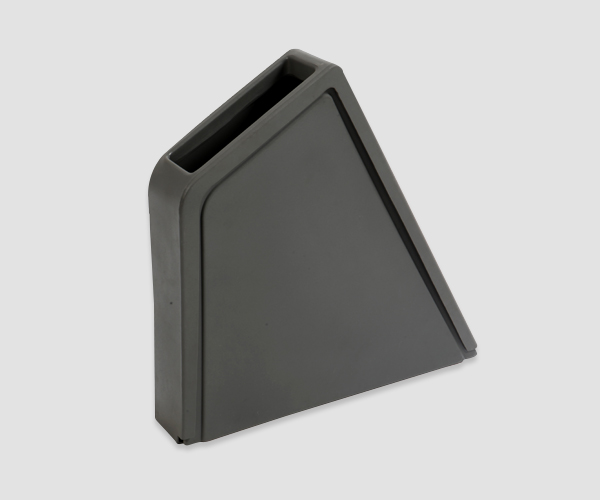

PE

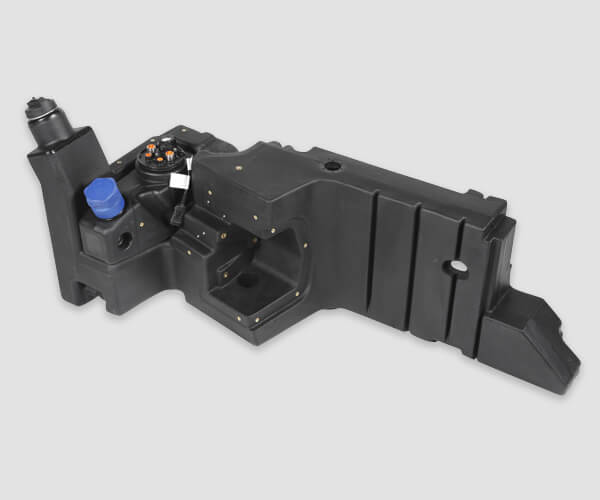

Polyethylene products showing high resistance to chemicals and environmental stress cracking (ESCR) with low temperature applicability are regarded as light-weight solutions. Our company manufactures wide range of polyethylene-based products from low density to high density polyethylene resins.

Previous

Next